Wholesale OEM China Wholesale Factory Direct Sale Aluminum Blow Mold Phylon Sole Die EPS Foam Outsole Mould

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for Wholesale OEM China Wholesale Factory Direct Sale Aluminum Blow Mold Phylon Sole Die EPS Foam Outsole Mould, Honesty is our principle, professional operation is our work, service is our goal, and customers’ satisfaction is our future!

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for China Soles Mold, Outsole Mould, Our team knows well the market demands in different countries, and is capable of supplying suitable quality products and solutions at the best prices to different markets. Our company has already set up a experienced, creative and responsible team to develop clients with the multi-win principle.

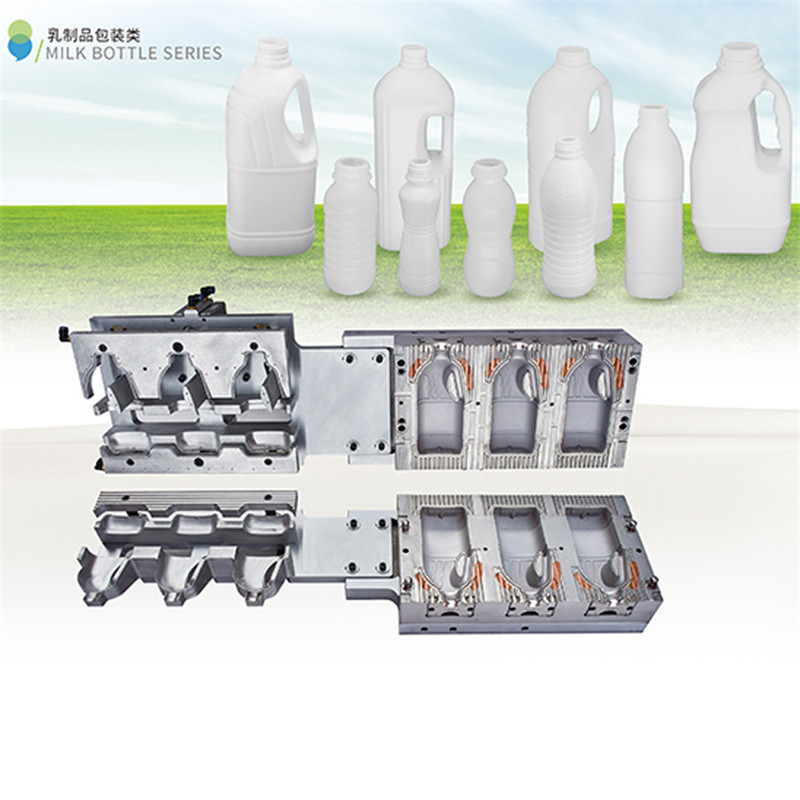

Efficient output

Cooling water to all corners,fast and uniform cooling,enjoy the fastest cycle time and make sure the bottle shap is perfect.

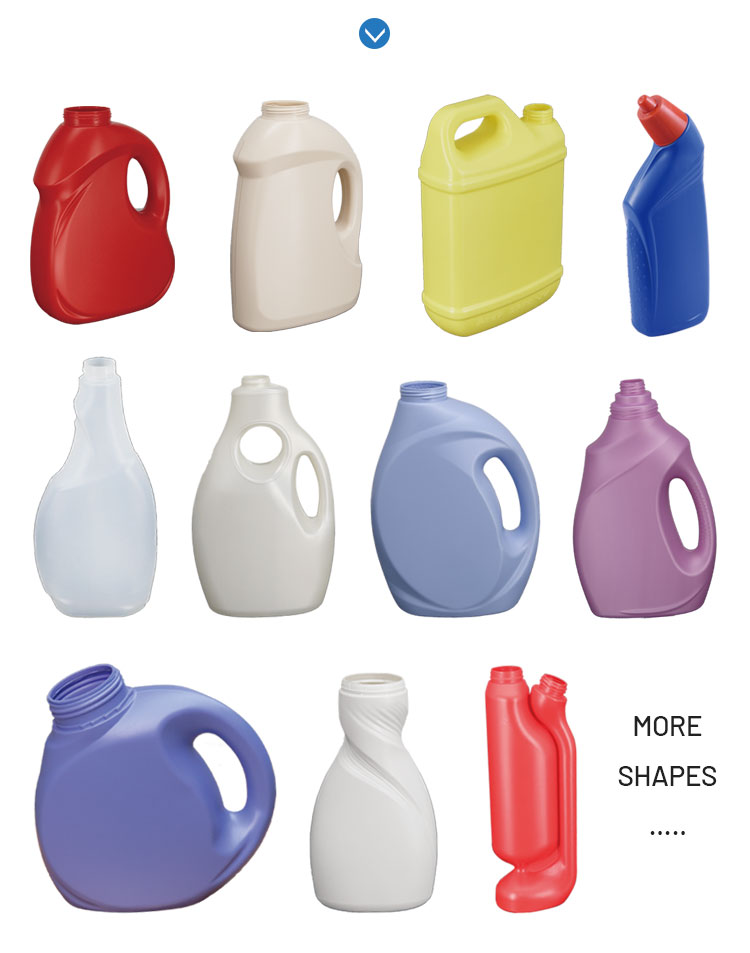

Bottle advantage

1,strong tightness,no leakage

2,Long distance transportation,express delivery,etc,drop to the ground without breaking.

Any design can be customized.

Desgin from the big frame to details

Product Parameter

Place of Origin:Guangdong, China

Brand Name:Singple

Model Number:XP2101789

Shaping Mode:Blowing Mould

Product Material:Aluminum+Becu

Product:Household Product

Product Name:blow molding hdpe

Cavity:1*4

Application:blow molding hdpe

Plastic material:HDPE

Mould material Option:45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc

Surface treatment:Polishing

Mold life:2 years

Mould base:HASCO standard, European standard, World standard

Equipment:CNC, Lathe, EDM, Wire Cutting, Drilling, etc.

Supply Ability

Singple preferred mold material

| Beryllium bronze – physical and mechanical energy parameters | ||||

| Becu name | Be-275C (C17100) | BeA-20C (C17200) | BeA-1C (C17500) | BeA-50C (C17600) |

| Density g/cm(20°C) | 8.09 | 8.3 | 8.62 | 8.62 |

| Thermal conductivity w/m.k(20°C) | 100 | 105 | 195 | 210 |

| Tensile strength MPa | 1140 | 1105 | 660 | 705 |

| Yield stress% | 1070 | 1035 | 520 | 520 |

| Elongation | 1 | 1 | 6 | 8 |

| Hardness | HRC46 | HRC43 | HRB96 | HRB96 |

| Electrical conductivity 2ACS% | 15 | 18 | 45 | 45 |

| Properties of beryllium copper | Beryllium bronze has excellent comprehensive properties. Its mechanical properties, such as strength, hardness, wear resistance and fatigue resistance.It is top one among copper alloys,and it’s thermal conductivity far exceeds that of steel and aluminum. | |||

| Application of extrustion blow molding mold | Thread,neck,handle and bottom cutting edge insert,blow pin | |||

| Properties and application of 7075 magnesium aluminum alloy | ||||||||

| Chemical composition | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti |

| ≤0.4 | ≤0.5 | 1.2-2.0 | ≤0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | ≤0.2 | |

| Physical properties | Coefficient of heat conduction | 0.2%Yield stress Rp0.2 | Hardness HB | Elongation | Modulus of elasticity | Density | Tensile strength | Specific heat |

| 173W/m.K | 455Mpa(N/mm²) | 150 | ≥6 | 71GPa | 2.81g/cm³ | 524Mpa(N/mm²) | 0.96J/g-K | |

| Characteristics | 1,High-strength heat-treatable alloy 2,Good mechanical properties 3,Excellent thermal conductivity 4,Easy to process,good wear resistance 5,Good corrosion resistance and oxidation resistance | |||||||

| Application of extrustion blow molding mold | Cavity,deflashing,deflashing cut | |||||||

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for Wholesale OEM China Wholesale Factory Direct Sale Aluminum Blow Mold Phylon Sole Die EPS Foam Outsole Mould, Honesty is our principle, professional operation is our work, service is our goal, and customers’ satisfaction is our future!

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for Wholesale OEM China Wholesale Factory Direct Sale Aluminum Blow Mold Phylon Sole Die EPS Foam Outsole Mould, Honesty is our principle, professional operation is our work, service is our goal, and customers’ satisfaction is our future!

Wholesale OEM China Soles Mold, Outsole Mould, Our team knows well the market demands in different countries, and is capable of supplying suitable quality products and solutions at the best prices to different markets. Our company has already set up a experienced, creative and responsible team to develop clients with the multi-win principle.